FH16是搭载沃尔沃新D17发动机的卡车车型之一。(沃尔沃)

FH16是搭载沃尔沃新D17发动机的卡车车型之一。(沃尔沃) 沃尔沃集团首席技术官Lars Stenqvist(沃尔沃)

沃尔沃集团首席技术官Lars Stenqvist(沃尔沃) 位于瑞典哥德堡的沃尔沃卡车装配厂内部。(沃尔沃)

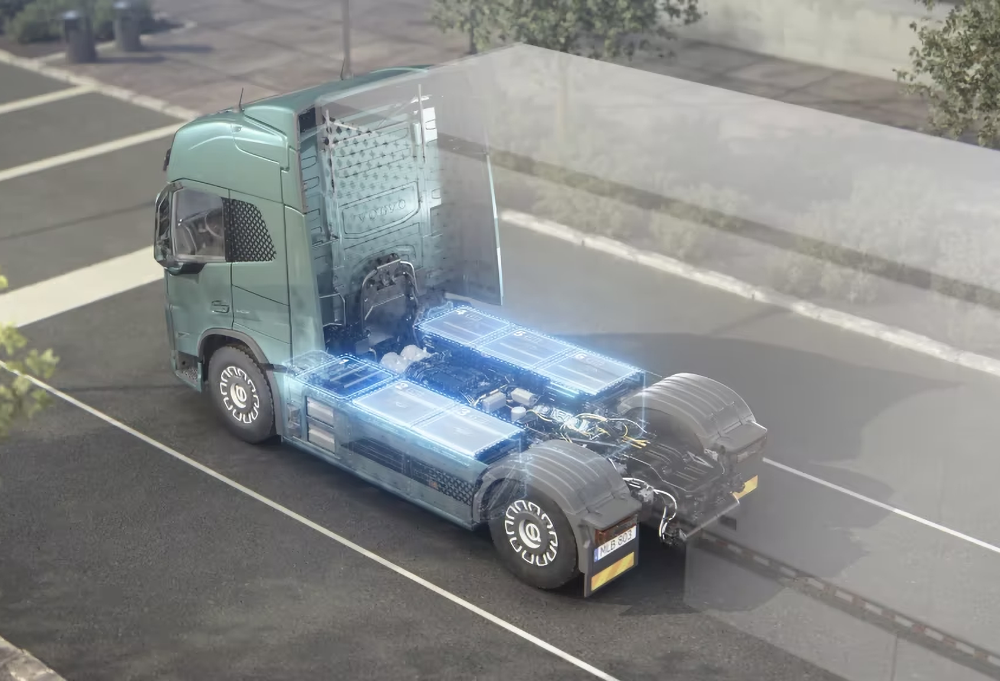

位于瑞典哥德堡的沃尔沃卡车装配厂内部。(沃尔沃) 沃尔沃FH和FM重型卡车使用三星SDI提供的NCA锂离子电池。(Ryan Gehm)

沃尔沃FH和FM重型卡车使用三星SDI提供的NCA锂离子电池。(Ryan Gehm) D17,沃尔沃最新的17L结构发动机。(沃尔沃)

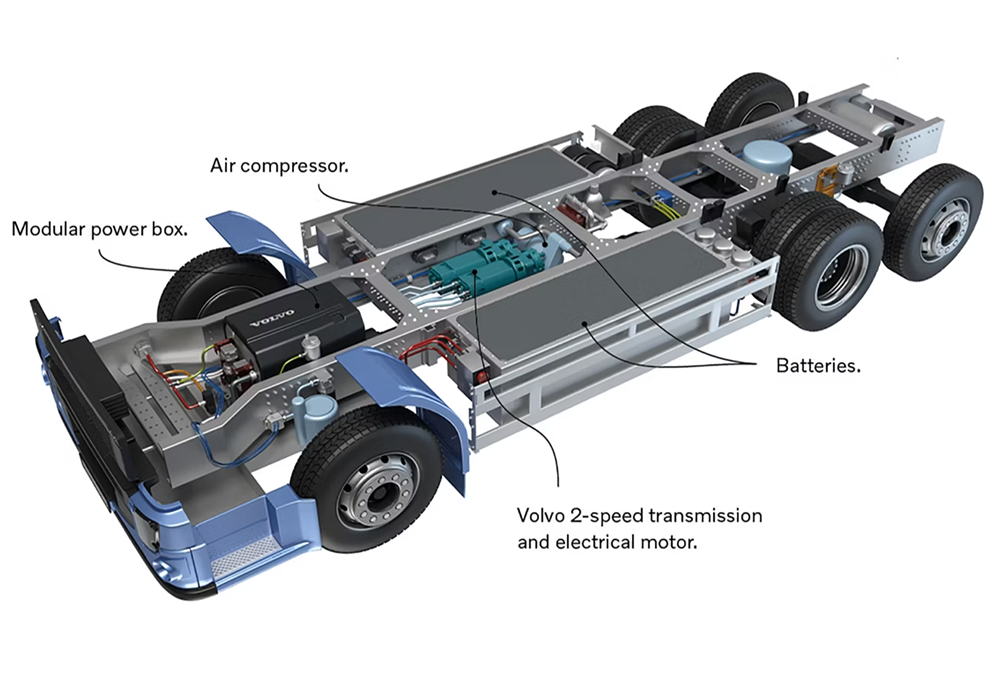

D17,沃尔沃最新的17L结构发动机。(沃尔沃) 沃尔沃在多种推进系统和技术的工程设计和研发方面进行了大量投资。(沃尔沃)

沃尔沃在多种推进系统和技术的工程设计和研发方面进行了大量投资。(沃尔沃) 沃尔沃预计,未来几十年,电池和燃料电池卡车将开始占据卡车市场的份额。(沃尔沃)

沃尔沃预计,未来几十年,电池和燃料电池卡车将开始占据卡车市场的份额。(沃尔沃)

沃尔沃卡车正引领到2050年实现净零排放的潮流,但其他OEM会跟随吗?

沃尔沃卡车坚信自己能在2040年前实现净零碳排放,为了实现这一宏伟目标,该公司采取了几近狂热的手段,并希望其他OEM效仿他们的做法。沃尔沃将其策略称为“通往净零之路”。

SAE受邀前往瑞典哥德堡,参观沃尔沃的多家工厂,并在其试验场试驾了最新的卡车车型。除了参观位于哥德堡市中心的新体验中心“World of Volvo”外,我们还得到了与沃尔沃工程师和高管直接交流的机会,以了解该公司如何实现其宏伟目标。

和大多数OEM一样,沃尔沃正在采取多管齐下的方法实现净零排放,并重金投资了多种推进系统和技术的研发工程。虽然沃尔沃认为纯电卡车必将在未来的重型汽车行业中占有一席之地,但同时也认识到,这并不是适用于所有市场和客户的万能解决方案。

在沃尔沃卡车位于哥德堡的主装配厂的生产车间里,这种理念的成果正得到彰显。在这里,传统的内燃机卡车与电动卡车依次有序生产。装配线采用鱼骨布局,卡车部件在各条独立产线上生产,然后汇聚到一条如同脊柱一般的工厂主线上。

据沃尔沃高管介绍,拟建工厂位于马里斯塔德市,选择那里建厂的部分原因是其靠近沃尔沃集团目前位于舍夫德的动力总成主厂。该地点距沃尔沃集团在哥德堡的研发中心和总部大约两小时车程。

“这些资产以及Proterra团队的专业技术是对我们现有业务的有力补充,使我们能够进一步加快纯电动业务布局,”Stenqvist在一份声明中说道。据报道,沃尔沃计划将Proterra作为供应商运营,并向选定客户供应电池组。

在动力技术谱系的另一端,沃尔沃新推出的D17发动机正为目前欧洲市场上出售的动力最强劲的卡车服务。在沃尔沃的哥德堡试验场,SAE通过试驾一辆FH16卡车体验了这款发动机的性能。虽然测试车挂载的串联挂车当时并无载重,但卡车在爬坡时的轻松表现着实令人印象深刻,表明其动力储备相当充足。

沃尔沃表示,所有功率等级的D17发动机均可使用氢化植物基燃油(HVO),700hp版本还可使用100%生物柴油(B100)。据悉,配备新D17发动机的沃尔沃FH16卡车将于2024年中期开始销售,并计划在今年下半年启动生产。

沃尔沃是如何将这些策略融合在一起?一方面,投资电动卡车(以及燃料电池)的生产,但同时,也在生产公司有史以来最大、最强劲的内燃机。乍看之下,这似乎与沃尔沃的净零排放目标背道而驰,但在这股斯堪的纳维亚式的疯狂背后确有其方法和科学依据。

根据沃尔沃引用的瑞典政府统计数据,这些更长、更重的拖车可使单条路线的能耗减少多达30%,对于整个运输业则减少约4-6%。据悉,这些数据也适用于其他推进系统,如纯电动和氢燃料电池系统。沃尔沃估计,一辆34.5米的牵引式挂车可以运输相当于两到三辆传统卡车的货物。

Alm表示:“我们正致力于实现我们的减排目标:到2030年,我们50%的新售卡车将实现零排放。到2040年,我们100%的新售卡车将实现零排放。到2050年,我们全球所有新售卡车都将实现零排放。”

Volvo Trucks is betting on themselves to reach the aggressive goal of net-zero carbon emissions by 2040. The company is taking an almost fanatical approach to its emissions reduction targets in hopes that other OEMs will follow their lead. Volvo refers to this approach as “The Road to Net Zero.”

SAE Media was invited to Gothenburg, Sweden, to tour many of Volvo’s facilities and experience its latest truck offerings at its proving grounds. In addition to touring the newly christened World of Volvo, the company’s new experience center located in the heart of Gothenburg, our group of select journalists was provided unfettered access to company engineers and executives to glean how the company plans to achieve its ambitious targets.

“We are not doing this simply because we have to,” said Roger Alm, executive VP of Volvo Group and president of Volvo Trucks. “We are taking this approach because we believe it is the right thing to do to preserve the environment for future generations.”

A multifaceted approach

Like most OEMs, Volvo is taking a multi-pronged approach to achieving net-zero emissions. The company has invested heavily in engineering and R&D for multiple propulsion systems and technologies. Though battery-electric trucks are certainly part of the picture in Volvo’s projection for the heavy-duty sector, they do not represent a solution for all markets and customers in the company’s view.

“Too many politicians across the globe are a little bit too trigger-happy and want to ban technologies instead of telling us what they want to achieve,” said Lars Stenqvist, chief technology officer of Volvo Group. “We don’t want governments to ban technologies, we want them to ask us what it is they want to accomplish, then let our engineers accomplish that goal.”

Nowhere is the commitment to this approach more apparent than on the shop floor at Volvo Trucks’ main assembly plant in Gothenburg, where traditional ICE trucks are built in series with its electric units. The assembly line is a fishbone layout, where trucks come down individual lines, but then converge into a single line to form the spine of the plant.

During the plant tour, SAE Media witnessed the marriage of both ICE and electric powertrains to their respective chassis, including the installation of Volvo’s new flagship D17 diesel engine. In addition to investing large sums into its R&D center for continued development of ICE and BEV powertrain technologies, Volvo also laid out plans for its new European battery factory in the Skaraborg region in Sweden.

According to Volvo executives, the proposed site in the municipality of Mariestad was selected in part due to its proximity to Volvo Group’s current main powertrain plant in Skövde. The proposed site sits roughly two hours from Volvo Group’s R&D centers and headquarters in Gothenburg.

During our stay in Gothenburg, Volvo executives detailed the purchase of and plans for Proterra, which was acquired by Volvo in the first quarter of this year. Volvo’s acquisition included all business assets of Proterra Inc. as well as the Proterra Operating Company. The firm was acquired for a reported sum of 210 million USD and included Proterra’s development center for battery modules and packs in California as well as its assembly factory in Greer, South Carolina.

“These assets and the skills and competence of the Proterra team are a great complement to our current footprint and enables us to accelerate our battery-electric roadmap even further,” Stenqvist said in a statement. Volvo reportedly plans to operate Proterra as a supplier and deliver battery packs to selected customers.

Mean and green ICE

On the other end of the propulsion spectrum, Volvo’s new D17 engine is powering some of the most powerful trucks currently on sale in the EU. SAE Media was able to experience this engine from behind the wheel in an FH16 truck at Volvo’s proving grounds in Gothenburg. Though the tandem trailers that were hitched to our test vehicle were unladen, the ease with which the truck moved them up grades was impressive, and it was apparent that there was plenty of power in reserve.

The D17 is Volvo’s latest 17-liter architecture with power outputs ranging from 600 to 780 hp (447 to 582 kW). Torque output ranges from 3000 to 3800 Nm (2212 to 2802 lb-ft). The D17 is outfitted with a single turbocharger as well as Volvo’s patented wave piston design that optimizes combustion and reduces emissions. The design is also shared with the D13 engine in the recently announced VNL for North America.

Volvo states that the new D17 is certified to run on HVO (hydrotreated vegetable oil) in all power ratings. The 700-hp version is also certified to run on 100% biodiesel (B100). Sales of the Volvo FH16 with the new D17 engine will reportedly begin in mid-2024, with production slated to begin in the second half of this year.

The big picture

So how do these strategies converge? Investing in the production of electric trucks (as well as fuel cells) while also producing the company’s largest and most powerful IC engine ever may seem counterintuitive to Volvo’s goal of net-zero emissions on the surface. But there is a method — and science — to this Scandinavian brand of madness.

Regulations that on one hand appear to be squeezing ICE out of the picture have opened opportunities for behemoths like the D17. For example, the Swedish government recently enacted new length and weight regulations for Class 8 trucks. These regs, which went into effect in December of last year, permit the use of combination trailers of up to 113 feet (34.5 meters) long with a GCW of up to 100 tons on specific Swedish highways.

According to statistics presented by Volvo from the Swedish government, it is estimated that utilizing these longer and heavier trailers reduces energy consumption by up to 30% for individual routes and by 4-6% when extrapolated across the transport industry. These figures also reportedly apply to other propulsion systems such as BEVs and hydrogen fuel cells. Volvo estimates that one 34.5-m tractor-trailer can carry the same freight as two or three conventional trucks.

That said, Volvo projects that battery and fuel-cell electric trucks will begin to take over share of the truck market in the coming decades. According to company projections, battery and fuel-cell trucks will overtake sales of ICE units sometime between 2030 and 2040, with market share between the three propulsion systems stabilizing around 2040.

“We are committed to our emissions goals: 50% of our new trucks will be zero-emission vehicles by 2030. And 100% of our new trucks will be zero emission by 2040,” Alm said. “Our entire global population of new trucks will be zero-emission vehicles by 2050.”

等级

打分

- 2分

- 4分

- 6分

- 8分

- 10分

平均分